In the weighing industry, “OEM” has specific technical implications beyond its general usage. Original Equipment Manufacturers fall into two distinct categories:

- Manufacturers building end-use machinery with integrated weighing capability, where force measurement is fundamental to equipment function rather than an add-on feature.

- Component manufacturers supplying specialized force transducers to equipment producers for integration into their mechanical systems.

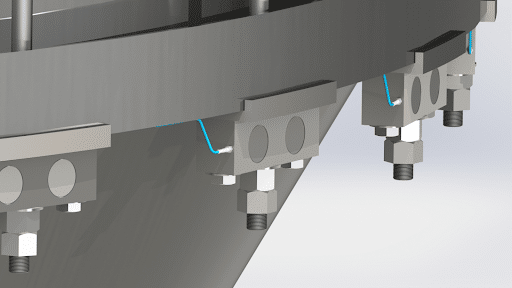

The engineering distinction is critical. When a load cell must function as a structural element within equipment rather than simply supporting a platform, the physics changes drastically. Force vectors become multi-directional which can result in significant off-axis components. Mounting constraints introduce parasitic loads not present during calibration. Temperature gradients create differential expansion between connected components. Vibration profiles include amplitudes and frequencies that standard cells aren’t designed to withstand.

Types of OEM Load Cells Available for Ohio Manufacturers

Load cells aren’t generic sensing elements; they’re specialized mechanical structures designed to convert specific force patterns into electrical signals. Selection requires matching the cell’s structural characteristics to the force transmission dynamics of your equipment:

Compression Load Cells

This broad category encompasses various structural designs including columnar, pancake, and shear beam configurations, all measuring compressive forces but through different mechanical principles. While seemingly straightforward, these cells face significant application challenges—particularly with moment loads or eccentric force application, conditions commonly encountered in equipment integration.

For OEMs building batching systems or press equipment where vertical force predominates, properly selected compression cells can work effectively—but only with engineered mounting solutions that maintain force vector alignment under actual operating conditions. This typically requires self-aligning load buttons, thermal isolation barriers, and side-load protection beyond what standard mounting methods provide.

The specific compression cell design must be matched to the application’s force characteristics, with single-point cells, canister designs, and multi-column arrangements offering different advantages depending on load distribution, environmental factors, and space constraints.

Tension Load Cells

Designed for vertical axial tensile force measurement, these cells require precise alignment with the force vector to prevent binding and off-axis loading that creates non-linear response. Angular misalignment exceeding 0.5° can introduce errors beyond 1% in standard designs—a tolerance frequently exceeded in equipment subject to thermal cycling and structural deflection.

For applications like hoists, winches, and material testing, these cells must also withstand shock loading frequently exceeding 200% of nominal capacity. Standard specifications typically address safe overload at 150%—adequate on paper but insufficient for equipment experiencing repeated start/stop cycles and dynamic loading.

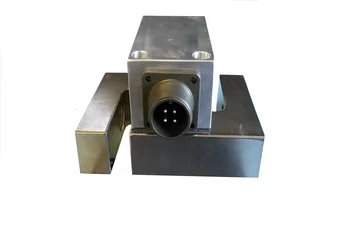

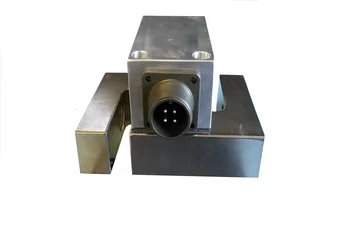

Load Pins

Perhaps the most elegant integration method—custom-engineered load sending pins with internal strain gauges designed as direct replacements for existing structural pins within equipment. The engineering complexity lies in their internal design: force concentration, strain gauge placement, internal wiring routes, and sealing methods all require specialized knowledge rarely found in generic suppliers.

For equipment manufacturers looking to add measurement capability with minimal mechanical modification, these provide significant advantages in crane sheaves, pivot points, and hydraulic cylinders—but only when designed specifically for the load distribution characteristics of the application.