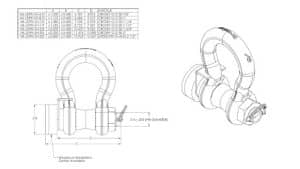

Our comprehensive service process starts with requirements capture & analysis, design drawings for approval, custom engineering with 3D and finite element analysis and simulation, and fabrication drawings and testing requirements. This systematic approach ensures that every solution we create precisely addresses the specific challenges of your application.

Custom Fabrication

Why does fabrication quality matter so much in measurement systems? Because force transmission paths fundamentally depend on mechanical precision. Minor machining variations, improper material selection, or inadequate heat treatment can transform a theoretically sound design into an unreliable field installation.

Our custom fabrication capabilities include:

- CNC Milling and Turning: Temperature-controlled machining environments with toolpath optimization for critical dimensions affecting strain distribution and signal generation.

- Material Selection Beyond Specifications: Rather than simply specifying “stainless steel,” we select specific alloys and heat treatments based on elastic properties, fatigue resistance, and environmental compatibility—critical factors for Nevada applications with extreme temperature cycling and potential chemical exposure.

- Environmental Protection Systems: Application-specific sealing methods and protective coatings designed for particular exposure conditions rather than generic environmental ratings that often prove inadequate in Nevada’s harsh industrial environments.

This fabrication focus delivers measurement systems with mechanical integrity that maintains force transmission accuracy despite thermal cycling, structural flexing, and environmental exposure that typically degrades commercial systems within months of field deployment.

Precision Machining

The performance of force measurement systems often depends on dimensional relationships maintained to tolerances far stricter than standard industrial machining. Key aspects include:

- Strain Section Optimization: Precisely controlled dimensions in force-sensing elements where variations of 0.001″ can significantly affect measurement characteristics and long-term stability.

- Surface Finish Control: Specialized finishing operations for strain gauge mounting surfaces where micro-texture affects bonding integrity and measurement stability under thermal cycling.

- Geometric Tolerancing: Complex relationships between multiple surfaces that affect force transmission paths and signal generation under various loading conditions.

- Heat Treatment Sequencing: Controlled thermal processing between machining operations to minimize residual stress while optimizing material properties for specific application requirements.

Nevada’s mining and industrial applications present particular challenges for these precision operations due to the heavy-duty nature of equipment operating in extreme environments. Our machining approach balances ultra-precision in critical areas with robust construction methods appropriate for field deployment in these demanding conditions.

See our engineering process in action

Innovative Engineering Solutions for Industrial Weighing Systems

Conventional weighing systems fundamentally assume controlled environments and ideal loading conditions—assumptions that rarely hold in Nevada’s industrial settings. Our engineering innovations address the realities of field deployment:

- Multi-Vector Force Analysis: Strain gauge configurations that measure primary force components while rejecting off-axis loading induced by thermal expansion, structural flexing, or operational dynamics.

- Thermal Gradient Compensation: Advanced temperature monitoring and correction algorithms that address non-uniform temperature distribution across mechanical systems—a common issue in Nevada’s outdoor installations with direct sun exposure.

- Resonant Frequency Mapping: Identification and mitigation of frequency-specific vibration components that create measurement errors at particular operational speeds or process conditions.

- Environmental Isolation Systems: Specialized protection methods for both sensing elements and signal conditioning electronics, addressing specific contaminants and exposure conditions rather than relying on generic IP ratings.

These innovations translate directly to industrial weighing systems that maintain accuracy in applications where standard solutions drift out of tolerance within months—from mining trucks operating in extreme temperature variations to process vessels subjected to thermal cycling and vibration from nearby equipment.